Repairs to inside cockpit walls:

So I thought that was the lot as far as cockpit wall cracks was concerned. But then I decided to take out the seat pans to check out the floor area, and found another set of cracks!

By now I’ve got that system down pat and it didn’t take long to cut out the cracked area, make up a plywood backing piece and epoxy/flock it in.

Tomorrow I’ll glue the original piece back onto the backing plate, that should be the end of that lot.

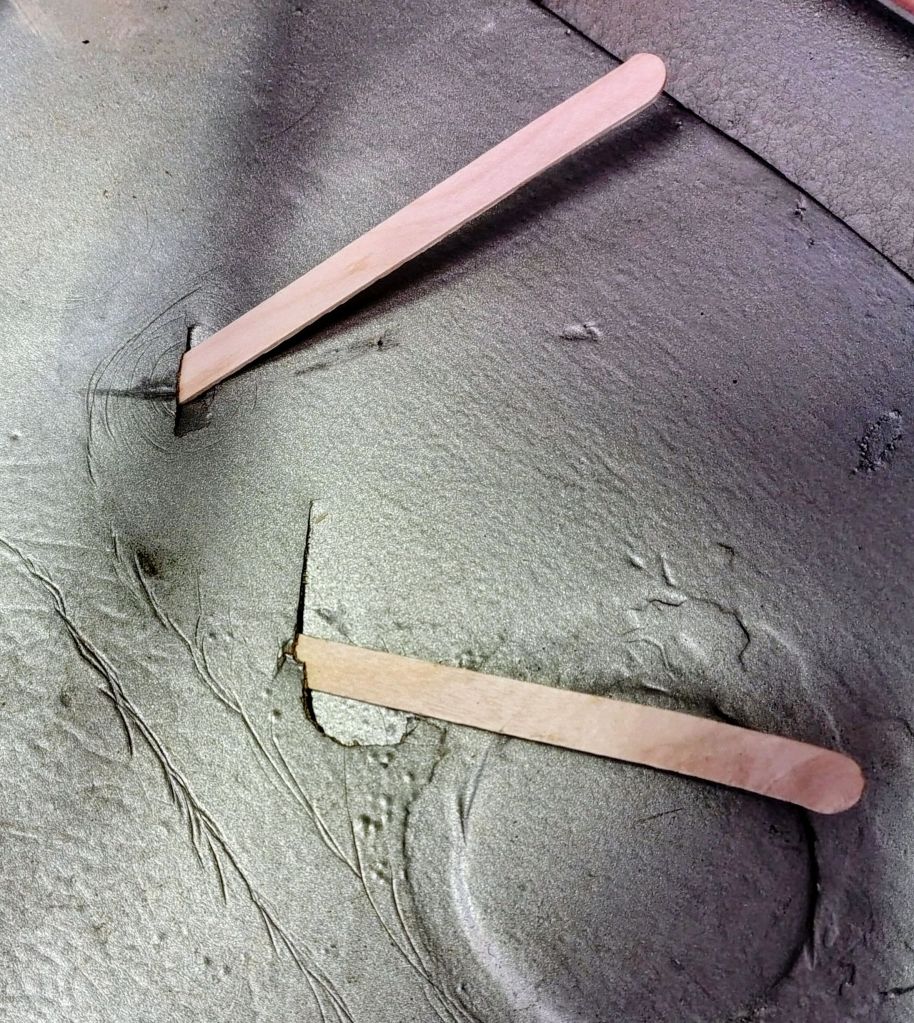

I also glued together the end of the skid which is composed of a sandwich comprising two Tassie Oak strps with a thin plywood strip in the middle. Below are before and after shots.

Yesterday at Mangrove I had a good look at the aileron fabric. While obviously showing its age, I believe it will easily last another year before the 50 year survey. I tried to find any de-glueing between fabric, ribs and gussets and could find none. The fabric is attached by wrapping around the ailerons, with a 50mm overlap at the trailing edge as required. Since Pete had a look at the ailerons down at STGC and found no flaws which would invalidate airworthiness in the short term (i.e.another year), I think we can safely defer the re-fabric of these control surfaces until the Form 2/Survey next year.

Leave a comment