Laurie got back from Qland and we launched straight into applying the Norseal epoxy filler, preceeded by a de-dusting of the surfaces with moistened Wettex.

We rolled on this very low viscosity mix in a couple of hours onto the fuselage, and another hour brushing onto the tail feathers. We only used half of the 2 litres we ordered since there was very little soaking into the plywood. Rather the coating was an extension of the original epoxy sealer applied at the factory all those years ago. On closer inspection it was noticable that the Norseal was filling the fine cracks which had developed, presumably due to thermal expansion and contraction that occured over the last nearly 50 years..

Because of the ease with which the rolling on happened, we decided to also roll the undercoat, rather than spray it on, after a light dry 240 grit sanding of the Norseal.

We’ve pencilled in the sanding for next Saturday, followed by rolling on of the undercoat on Monday.

If that turns out as expected quality-wise, we will also roll on the finish coat. Not having to contend with overspray and its attendant mess all over the shop has great appeal!

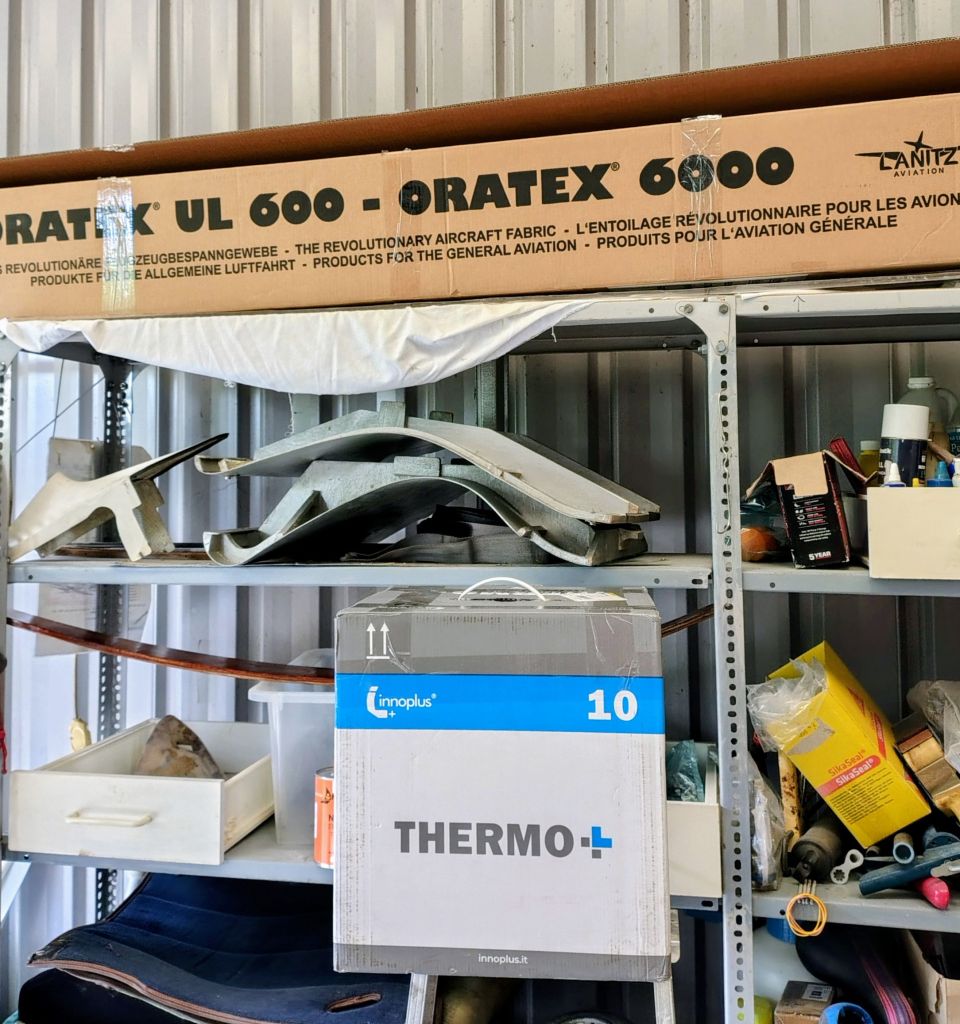

In the middle of our paint job, a courier arrived with our Oratex fabric order.

The special glue comes in a thermo box to maintain the brew within acceptable tolerances during its journey from Germany.

The blue colour in the photo is nothing like the actual, we’re both really happy with it. The size box it came in allowed us to put Pete’s 3 m of white 600 grade in with our 5 m of blue.

Pete mentioned that the width of his white stuff was actually 1.9 rather than the advertised 1.8 m, and our blue one is identical.

At current projection we should be able to finish the painting by the end of the month and start putting the Oratex covering immediately thereafter.

Leave a comment