The last few days have revolved around the luggage deck. Significant damage was found which needed assessment by Pete. Following his visit I delved further into this area.

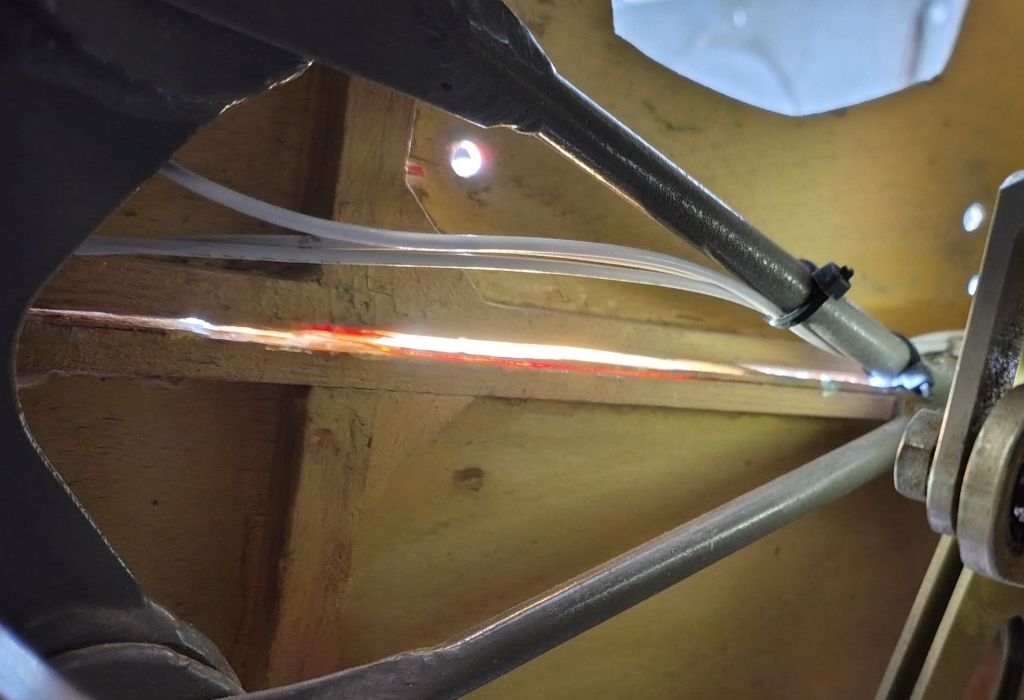

This shows the central support cracked along its entire length. At least conttributing to this failure waa the use of fairly large wood screws which likely initiated this crack. The upshot: the entire luggage deck needs replacing.

Pete approved this suggestion as this area is non-structural.

Removing the old deck revealed a number of other issues. The antenna had been installed in a position which allowed the port aileron pushrod to rub against it. The damage appears to be superficial, but I’ll get Pete to give it the ok for continued service.

The first photo shows the rubbing on the pushrod, the second the black spot on the antenna shaft where the pushrod rubbed through the outer white insulation.

A new ground plane in the form of a thin aluminium sheet will be provided and the antenna relocated to a safe position.

When we first inspected this area we scratched our heads about why the shelf was cut in half down the middle. This puzzle was readily solved when realising that it is impossible to install this shelf as a single piece. So it was originally cut into two halves and then glued down on the frame. However, given no cross support for the shelf above the main spare carry-through, when the centre longitudinal support broke in half there was nothing to stop the entire deck to collapse onto structure below. It was resting on the main pivot shaft for the ailerons and airbrakes.

The new frame is designed to allow easy removal of the shelf. Attachment will be by M5 nut plates in the frame, which was made from Tassie Oak and Grandis Eucalypt. When it’s all done it will be epoxy-coated and painted.

Apart from eliminating the aforementioned defects, the removable deck will also facilitate much easier inspection and maintenance of all of the important mechanisms below the shelf.

Inspection of these mechanisms showed that all appears in good order. While there is some free play in the bell crank bushes for ailerons and airbrakes, it is within allowed tolerances according to the Bocian service manual (<0.12 mm). All will be cleaned and lubricated.

However, the front stick exhibits some free play which is well outside this tolerance and will need to be addressed. This has been noted by Col Veal following a previous Form 2 inspection.

Another bit of mystery found in the very bottom of the fuselage about a metre behind the cockpit is a cut off control cable – no idea about its original purpose. It seems to be quite secure. I’ll have to put a camera on a stick to get a photo for this.

The battery tray will also be relocated. At present there is wiring for a second battery, but we don’t intend to use this. I also don’t like the battery sockets installed into the floor of the shelf, since water or other liquid could collect and short things out (have I mentioned that I was in a K7 which caught fire during a check flight back in the 70’s? Not electrical but memorable all the same!).

Leave a comment